Replacement Sifters Screens

High Quality Replacement

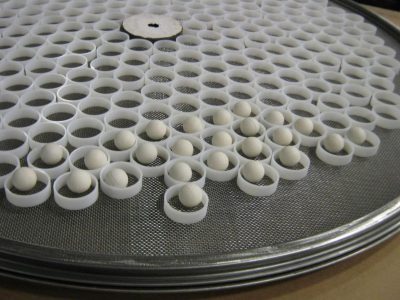

Round & Circular Sifter Screens

High Quality Replacement Round Screens,

Ultrasonic, Rectangular and Circular Sifter Screens

With our own specialized screen re-screening production facility, VibraScreener is able to provide high-quality replacement circular sifter screens for almost all models of round vibrating screeners and industrial sifters, regardless of the brand.

In addition to our own products, we offer replacement sifter screens for Sweco™, Kason™, Rotex™ and other industrial sifters and screeners. We are also experts in re-meshing your current circular screen frame with the highest quality wire cloth mesh, in some cases for a fraction of the price of others OEM’s. Compared to the cost of buying an entire replacement industrial sifter screen, this process helps save the cost of a new frame, especially for larger diameter screens. We can also supply original spare parts for VibraScreener round sieves screens and industrial sifters as well as for other brands of round screeners and rectangular screen separators.

Competitive Prices

In addition to our own products, we offer replacement sifter screens for Sweco™, Kason™, Rotex™ and other industrial sifters and screeners. We are also experts in re-meshing your current circular screen frame with the highest quality wire cloth mesh, in some cases for a fraction of the price of others OEM’s. Compared to the cost of buying an entire replacement industrial sifter screen, this process helps save the cost of a new frame, especially for larger diameter screens. We can also supply original spare parts for VibraScreener round sieves screens and industrial sifters as well as for other brands of round screeners and rectangular screen separators.

At VibraScreener we offer replacement circular sifter screens for round separators for Sweco®, Kason®, Midwestern®, Russell Finex® and other round sifters and screeners. We can also re-mesh or re-screen your current round sifter screens frame with the highest quality wire cloth mesh in stainless steel 304, 316 and magnetic 430. This can be more cost effective compared to buying new replacement round separator screens, this process helps save the cost of a new round sifter screen frame, especially for larger diameter separator screens. We can also supply original spare parts for VibraScreener round sieves screens and round sifters as well as for other brands of round screeners and rectangular screen separators. Round sifters screens are available for all diameters 24”, 30”, 40”, 48”, 60” and 72” circular screens to fit all round SWECO® vibratory separator screens with high quality replacement mesh screens to fit SWECO® replacement screens.

*** VibraScreener Inc. is not affiliated with or related to any of the brands mentioned above.

*** VibraScreener Inc. is not affiliated with or related to any of the brands mentioned above.

*** VibraScreener Inc. is not affiliated with or related to any of the brands mentioned above.

Quality First

Cost Savings

Our stress on high-quality replacement industrial sifter screens relies on saving you time and money. Our circular screens last longer due to our high-tech tension methods and strong bonding technologies. This indeed can be reflected in longer screens replacements periods in your vibrating round screeners which saves your company time and money.

Improved Quality

Consistent and accurate mesh apertures throughout the entire screen surface not only help increase capacity but also improves the quality of your products as ensure all unwanted oversize contamination is removed from your product and your round screen industrial sifters are performing at their optimum level. We also use the highest quality of stainless steel circular screen frames for the strictest sanitary applications.

Rapid Turnaround

Deploying efficient manufacturing and using modern tooling in our re-screening process we can achieve faster turnaround and deliveries in replacement circular sifting screens for our customers. This is aimed to benefit our customers become more productive and keep their plants running smoothly. For more information and prices on our re-meshing services and replacement industrial sifter screens, please get in contact with one of our technical representatives today.

Longer Sifter Screen Life

Because we only use the highest quality wire mesh and high resistant FDA approved adhesive in our re-screening process and our replacement sifter screens, we are able to increase the life of your circular industrial screens regardless of the material you are screening. Also important, our experienced technicians understand the correct tension that is needed for each mesh micron size for a correct stretching to ensure a longer life for your round sifter screens and better performance of your vibrating screening machines.

Reduced Downtime

By only using high-quality wire mesh with accurate apertures and applying precise tensioning on the mesh we extend the life of your replacement circular sifting screens and reduce the premature breakage of them. This translates into fewer screens changes which results in more productivity and less downtime in your plant, leaving your operators with more time to perform other tasks.

Increased Productivity

With correct and accurate micron size apertures we ensure you get consistent throughput and fast screening of your products throughout the entire round screen surface, this of course increases your productivity and contributes to the profitability of your company.