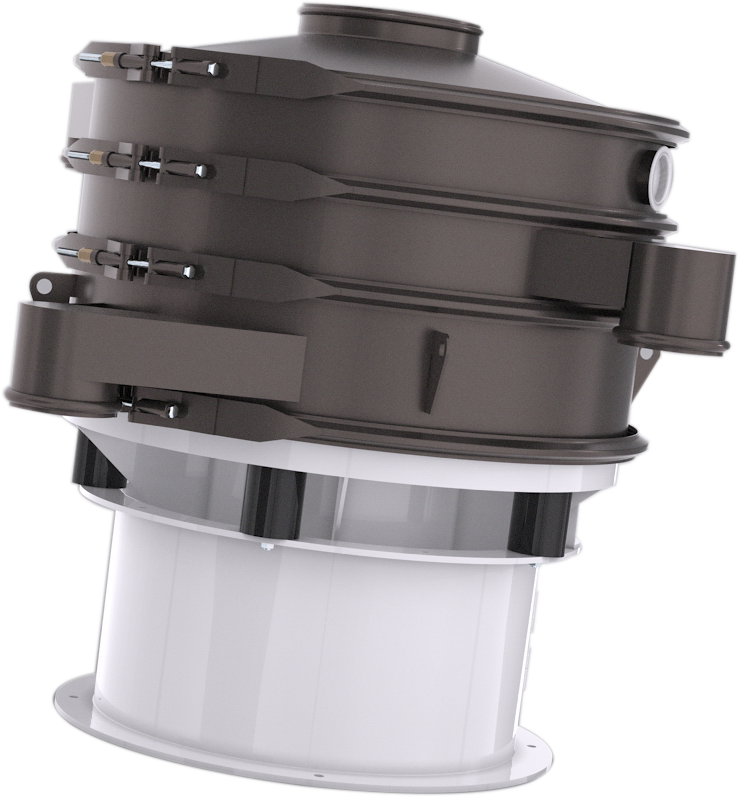

Ranger Separator™

Ranger Separator™

Benefits of the Ranger Separator™

Obtain the correct product size in a compact design and with ease of mobility!

Rubber Suspensions – Controlled Vibration

The Ranger Separator Vibrating Separator is equipped with 4 rubber mounts giving the sieve a more stable vibration, perfectly isolating vibration to transmit to the base of the screener. Contrary to metal springs in conventional round separators, the rubber suspensions allow more force to be applied directly to the circular screen surface and higher sieving capacity is achievable.

Higher Capacity

Because this round vibrating screener separator is mounted on rubber mounts higher force can be applied, translating into a higher throughput. With the rubber suspensions technology a more stable and controlled vibration is acquired in this circular vibratory screener, allowing more materials to pass the screen easily and faster. These robust rubber suspensions also help the vibratory screener separator increase throughput by allowing more vibration on the screen surface rather than spread all over the entire screening machine.

Quick Adjust™ Weight System

The Ranger Separator™ vibratory shaker features the Quick Adjust™ weight system, which helps set up and change the settings of the vibration without the need of tools and in a few seconds. This technology also allows operators to change the lead angle and vibration force without having to take apart the screener deck, which helps reduce downtime and increase productivity.

Accurate Separation

The Dynamic Screener™ was designed to have easy access to the sieving contact parts, including the screen mesh. This vibratory sieve features a small footprint with minimal contact parts and this industrial vibrating screener quick release clamps permit operators to replace the screen mesh in just seconds, contrary to similar circular industrial sieves with larger and heavier contact parts and/or difficult to maintain and operate toggle clamps.

Lower Noise Level

Advanced rubber suspensions make the Ranger Separator™ a high efficient round vibratory screening machine and this technology makes this circular vibratory separator incredibly silent compares to conventional round vibrating screeners.

Small Footprint

Despite its superior design this vibratory separator differentiates from its counterparts because of its small height. This circular vibrating screener uses a pedestal base, which is compact and does not require excessive headroom in the installation and process. This base also makes the Ranger Screener low maintenance as no shaft and bearings are need it.

Client Testimonials

![PO#_3516(RY16002)[62]hhhg](https://devtestlink.com/vibrascreener/wp-content/uploads/elementor/thumbs/PO_3516RY1600262hhhg-scaled-qx3rqjdgem7yitsnpya76vvauy5248ojm7ru9z4gio.webp)