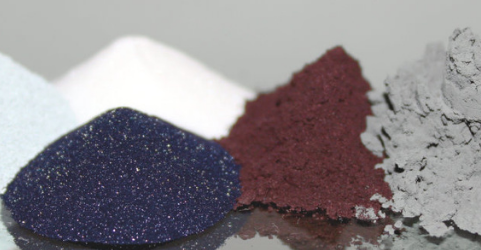

Metal Powder

Because we understand how important is sieving and screening in the manufacturing of metal powder, we take responsibility for the success of our metal powders manufacturer customers. Our vibratory sifting screens and industrial separators are manufactured as heavy and robust as the metal powders they are designed to sieve and classify. We are aware that as much as it is blending, compacting and sintering also screening is essential in the production of metal powders and the quality is perceived by the final customers.

Utilizing higher forces and superior designs our round separators and rectangular screeners are built to increase capacity and reduce downtime in metal powders manufacturing plants. We are also constantly innovating our sieving machines to make metal powder production more efficient and cost effective. Below are some of our innovative vibratory sieves and round separators most used to check screen and classify metal powders:

These vibratory rectangular separators specialize in separating and grading a wide number of recycling materials, utilizing higher forces and advanced counterweights technologies, to control material flow pattern on the screens, we are able to get a more accurate separation of materials. Below are some of the recycling materials we are able to classify:

- Papers

- Plastics

- Aluminum

- Cans

- Rubber

- Cardboard

- Scrap tires

- Garbage

- Metals

- Food waste

- Glass

- Construction materials

- Demolition materials

- Industrial materials

Why VibraScreener™?

We designed VibraScreener™ metal powder classifiers to provide many key advantages in today’s competitive manufacturing industry. We all know how important it is to have equipment that actively contributes to your bottom line, which is why our metal powder sifters and related products deliver

Low Maintenance Requirements

Thanks to our innovative ceramic sifting technology that filters out impurities while decreasing product losses.

Exceptional Productivity

Thanks to the high-capacity design and low maintenance requirements of our ceramic screener machines.

Small Footprint

Making the most of your floor space is a key priority for many organizations. Our small-footprint metal powder sifters make room for your team to move freely, reducing the risk of an accident and keeping workflows running smoothly.

These are just a few of the reasons major manufacturers — including Fortune 500 and multinational corporations — choose VibraScreener™ products for all of their metal powder sifting needs. Whatever the product and process, we can match your organization with the separator, sifter and screener that will drive productivity and profits.

To learn more about how our industrial screeners and round separators help improve productions of metal powders, please contact us to get free advice from one of our technical specialists in the metallurgy process.