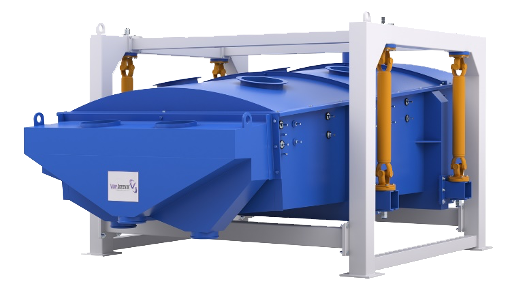

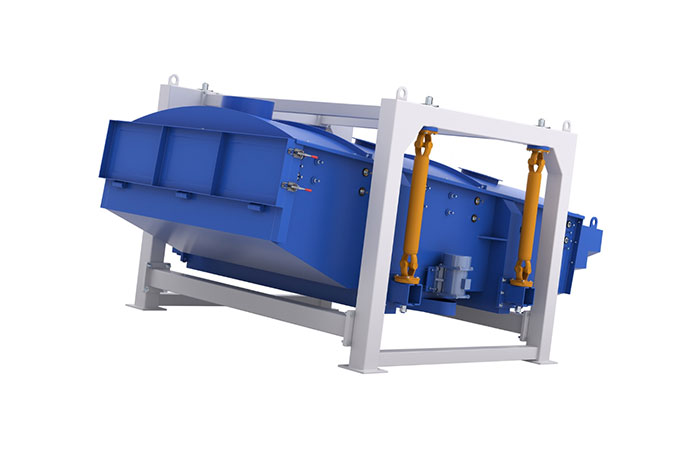

GyraSift™

GyraSift™

Benefits of the GyraSift™ – Gyratory Sifters / Screeners

Improved productivity

The GyraSift™ gyratory sifter increases productivity in your plant by reducing downtime and increasing capacity. Featuring advanced designs and technologies this industrial sifter eliminates the headaches experienced by operators in other traditional vibratory sifters.

Higher sieving capacity

Implementing higher frequency and adding more revolutions per minutes, this modern screening machine provides greater throughput compared to competing industrial vibrating sifters.

Low maintenance

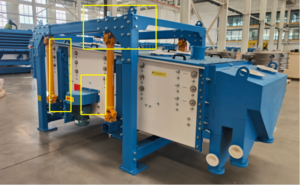

The easy to open doors to clean, replace and inspect the mesh screen, along with a low maintenance drive and screen assembly, the GyraSift™ is a cost-effective gyratory screening machine to own.

Even product distribution – much cleaner separation

With a side by side gyratory motion and a feed distributor the GyraSift™ industrial sifter is capable of providing a much better separation, which improves your product quality and build customer trusts. This technology also helps this gyratory screening equipment separate material with different shapes in different angles, that otherwise will pass the screen with a vibratory action, making the GyraSift™ a one of its kind gyratory screener.

Easy access to the screens – operator friendly

Featuring easy to open hinged doors from both ends, the GyraSift™ gyratory screen makes the operators’ job easier and faster, improving your plant productivity and reducing downtime.

Easy-to-tension screening media

With its tension in place technology the GyraSift™ gyratory screener makes it easier for operators to tension the screens in every deck without having to dismantle the screener decks. With hook style screens, operators can easily adjust and tension screens from outside this screening equipment – this also eliminates the need for multiple screens panels, reducing downtime.

Design of the Gyrasift™ — Gyratory Sifter Equipment and Screeners

- Side-to-Side Motion: With its gyratory sifter motion, the GyraSift™ provides exceptional screening quality. By separating materials of varying shapes, which is typical of raw dry goods, your company can maximize its production and product quality. This could lead to gains in revenue by building your consumer base and their confidence in your items.

- High-Throughput Screening: With its large number of revolutions per minutes, our gyrasifter equipment delivers an unparalleled level of throughput screening for dry materials, such as pharmaceutical products. This feature provides your operators and facility with the ability to optimize the quality and distribution of your goods, which can help you expand your reach and revenue.

- Hook-Style Screens: Thanks to its convenient hook style screens, our GyraSift™ industrial equipment provides operators with a hassle-free method for modifying screens without imposing unnecessary downtime on your facility. This engineering feat also saves your company the cost and maintenance of maintaining multiple screen panels, which lets you maximize your uptime.

- Easy-Tension Size Support: With its innovative design, our gyrasifter equipment offers compatibility with multiple sizes of easy-tension screening media. That feature lets the GyraSift™ support a range of dry application processes, which helps your company adapt to changes with ease and boost your overall production without sacrificing quality.

Client Testimonials