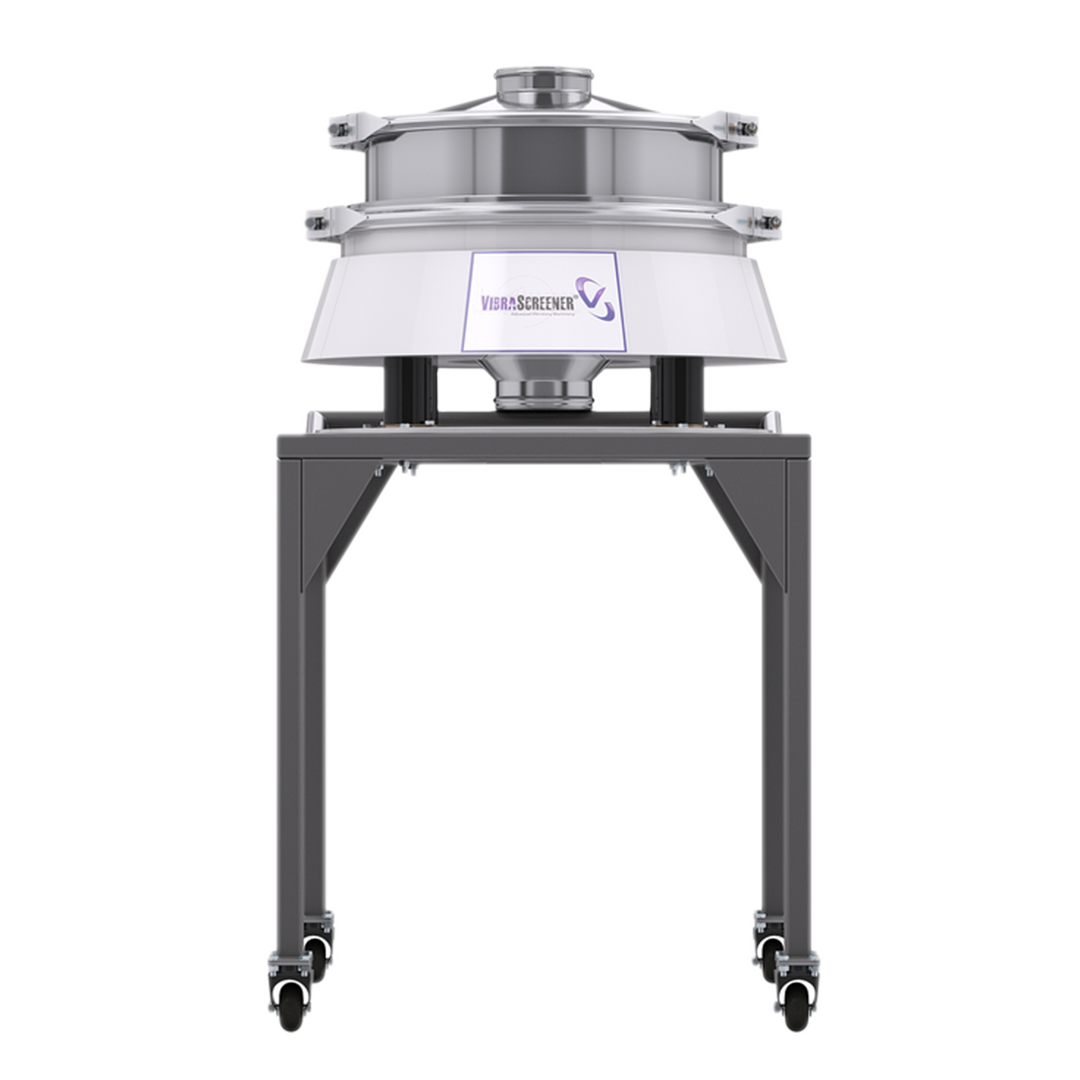

Dynamic Screener™

Dynamic Screener™

Benefits of the Dynamic Screener™

Improve your Product Quality and Protect your Reputation!

Higher Capacity

With its straight thru design more good product can pass the vibrating screen easily and faster with this industrial sieve. Solids rubber suspensions on this vibratory screener also help increase throughput – this is because this technology allows more vibration to be applied directly on the screen surface of the sieve.

Rapid To Replace The Screen Mesh

The Dynamic Screener™ was designed to have easy access to the sieving contact parts, including the screen mesh. This vibratory sieve features a small footprint with minimal contact parts and this industrial vibrating screener quick release clamps permit operators to replace the screen mesh in just seconds, contrary to similar circular industrial sieves with larger and heavier contact parts and/or difficult to maintain and operate toggle clamps.

Lower Noise Level

Advanced rubber suspensions make the Dynamic Screener™ a highly efficient industrial screening machine and this technology make this high-performance screener incredibly silent for a smooth sieving operation.

Easy To Clean And Dismantle

The Dynamic Screener™ is designed with operators in mind and the design of this circular vibrating screen allows easy access to the sieving contact parts to be clean, it also enables operators to change the screen when needed in seconds, unlike conventional industrial sieves.

Improves Your Product Quality

Due to its advanced design, the Dynamic Screener™ circular vibrating screen is designed to remove all impurities and contamination from your product. Because an oversize spout is often not necessary in in most applications for this industrial sieve, the possibility of losing good product with this vibrating screener is commonly eliminated.

Design of the Dynamic Screener™

Quick-Release Clamps

With our quick-release clamps, it’s a fast and straightforward process for staff to remove and replace your dynamic screening equipment’s screen, as well as to clean the sieve. This seamless process reduces the use of unnecessary labor and prevents contaminants from entering your screener, which supports a clean workspace and the compact size of the Dynamic Screener™.

Ultra-Hygienic Polish

With our ultra-hygienic finish, it’s a simple process to clean our dynamic screeners. This polish also extends to contact parts on the microbiological level, which provides your company with the peace of mind that your products are safe and free of contamination, thus ensuring your brand remains trusted by consumers.

Straight-Through Build

With our straight-through build, it’s feasible to process more materials at a time. This feature contributes to higher production goals, which can lead to increased revenue, plus the ability to meet the needs of new clients. Our dynamic screening solution’s circular vibrating screen also ensures the quality of your screening and final product.

Gap-Free Design

With our low-profile build, it’s a convenient process to install, maintain and use our dynamic screening equipment. The minimal contact parts of the Dynamic Screener™ also reduce the threat of cross-contamination. If your facility includes a fleet of our dynamic screening solutions, cross-contamination is often a non-issue due to our gap-free design.

Low-Profile Construction

With our low-profile build, it’s a convenient process to install, maintain and use our dynamic screening equipment. The minimal contact parts of the Dynamic Screener™ also reduce the threat of cross-contamination. If your facility includes a fleet of our dynamic screening solutions, cross-contamination is often a non-issue due to our gap-free design.

Client Testimonials

If you would like more information on the Dynamic Screener™ vibratory sieve or any other VibraScreener® high quality circular industrial screener, please contact us today to learn more from one of our technical engineer experts in vibrating screening and sieving equipment.